EASA Landing Gear Maintenance Considerations

Introduction

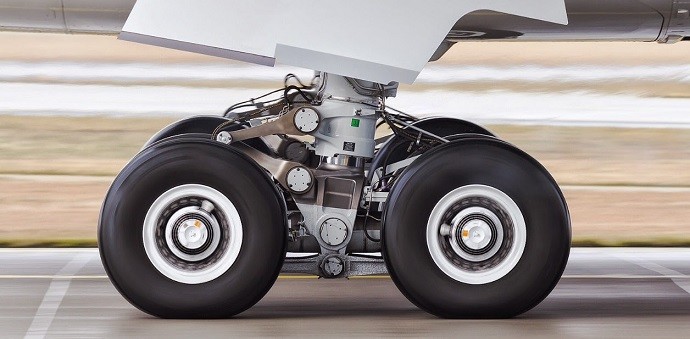

ATA Chapter 32 includes the Landing Gears together with the Wheels and Brake Systems. Together they create a significant maintenance requirement throughout the duration of the operation of the aircraft. All ATA Chapter 32 components are subjected to Stress and Wear during continuous operations.

Chapter 32 aircraft maintenance requirements also call up activity on landing gear doors, retraction system, hydraulic control valves and components as well as steering and indication. Wheel and Brake Components are usually on condition and the Landing Gear itself is typically a hard-timed component

Landing gear maintenance is generally referenced to Flight Cycles (FC) or Years in Service and consists of a range of activities including routine maintenance (mostly lubrication) repairing non-routine (NR) defects, together with shop visits (SVs) for the accomplishment of overhaul processes.

With a full understanding of the maintenance requirements it is relatively straight forward to determine when the landing gear will require a shop visit and whether it will be driven by calendar or FC parameters.

Maintaining an inventory of Landing Gear can incur significant expense and airlines typically avoid the cost by relying on contracted specialist providers or the original equipment manufacturer (OEM), which poses additional logistical consideration for airlines.

The maintenance requirements for Wheels and Brakes are clearly affected by flight cycles and require regular inspections to ensure continuing integrity.

In Service Maintenance Considerations

The original equipment manufacturer (OEM) component maintenance manuals (CMMs) provide guidance regarding what repairs may be carried out during overhaul and what parts require mandatory replacement.

During service it is expected that defects will be found during either line or base maintenance. Such activities can be supported by inspection. Typical techniques to support heavy landing gear maintenance include engineering, plating and machining, NDT painting & assembling; and bush manufacturing.

Overhaul Considerations

Landing Gear Removal requirements are determined by the MPD or operator aircraft maintenance program (AMP) Taking place when an overhaul is needed, when a repair is needed, or if the operator wants to swap gears.

Landing gears tend to be overhauled every 10 years. “These can be overhauled any number of times as long as the total life of the gear, usually set by the OEM at 60,000-70,000FC, is not exceeded.

The total safe limit of the components is determined in the MPD Typical safe life limits for new components range from 50,000FC to 100,000FC.

An overhaul workscope for the landing gear largely comprises routine work, so a large percentage of costs are predictable.

A typical Workscope requires all components to be inspected according to CMM and TCH / OEM guidelines, an example restoration could be to returning components to a Standard design condition by replacing worn bushings, replacing the sacrificial/protective finishes that protect the parts from corrosion, and inspecting for and correcting defects.

Exchange Landing Gear Considerations

The main landing gear components requiring hard time overhaul is similar for both Boeing 737NG and Airbus A320 aircraft. This consists of the main landing gear and dressing assembly, a side stay with locking actuator, and retract actuators, in addition the forward and aft pintle or trunnion pin assemblies. Boeing also include the uplock assembly for overhaul.

It is not uncommon for a full landing gear overhaul maintenance program to take more than 45 days, this is a considerable down time and would typically exceed the maintenance check by a significant margin.

An exchange program provides for a solution which will enable the maintenance check to be carried out in the minimum time. (Providing it is acceptable within the Lease Agreement) Exchange Options include the provision of a spare unit so that the airline receives its own landing gear back after the overhaul, or by a direct exchange.

In the case of a full exchange a replacement landing gear is requested from a suitable vendor after considering back to birth traceability as well as PMA acceptability issues. (Works both ways as the vendor will also look very hard at the gear which is being offered for exchange.

Once all parameters have been examined and considered the vendor will normally provide a quotation which if accepted will mean the replacement landing gear will be available on dock to ensure minimum down time

Landing Gear Overhaul Cost Considerations

A significant portion of landing gear maintenance costs can be fully understood and predictions developed within an overhaul workscope.

The standard fixed overhaul fee typically covers the routine workscope, labour, tooling, consumables and the landing gear shop's routine overhead. Additional items are costed separately including NR tasks, service bulletin (SB) tasks as well as any other requirements including airworthiness directives (ADs)

Sofema Aviation Services www.sassofia.com provides training for EASA Compliant CAMO Engineering teams. For details please see the website or email office@sassofia.com

CAMO Maintenance Planning and Control Director at iaa.ir. Aerospace Engineer. Licensed aircraft maintenance engineer. Airworthiness engineer

1yHi, is there any valid document from Boeing stating that the landing gear overhaul (calendar) is from first installation on A/C? Thanks